The Production Process of Mainstream Resistor Factories

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling the flow of electric current. They are essential for regulating voltage, dividing signals, and protecting sensitive components from excessive current. The resistor manufacturing industry has evolved significantly over the years, driven by advancements in technology and the growing demand for electronic devices. This article aims to explore the production process of mainstream resistor factories, shedding light on the intricate steps involved in creating these vital components.

II. Types of Resistors

Resistors come in various types, each designed for specific applications. Understanding these types is essential for grasping the production process.

A. Fixed Resistors

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and are often used in high-power applications.

2. **Film Resistors**: These include carbon film and metal film resistors, which are created by depositing a thin layer of resistive material onto a substrate. They offer better precision and stability compared to carbon composition resistors.

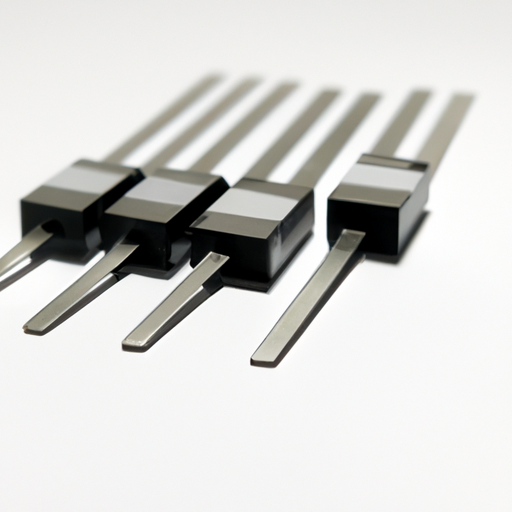

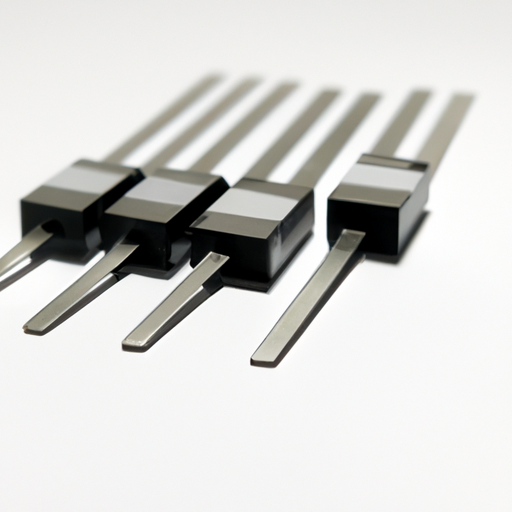

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic core, these resistors are capable of handling high power and are often used in applications requiring high precision.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in volume controls and other applications where variable resistance is needed.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are used in applications like dimmer switches.

C. Specialty Resistors

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure and are commonly used in light-sensing applications.

III. Raw Materials Used in Resistor Production

The production of resistors requires a variety of raw materials, each contributing to the final product's performance and reliability.

A. Conductive Materials

1. **Carbon**: Used primarily in carbon composition and carbon film resistors, carbon provides a stable resistive element.

2. **Metal Oxides**: Commonly used in film resistors, metal oxides offer high stability and reliability.

3. **Metal Wire**: Essential for wirewound resistors, metal wire is typically made from materials like nickel-chromium or copper.

B. Insulating Materials

1. **Ceramic Substrates**: These are used in wirewound and film resistors to provide electrical insulation and mechanical support.

2. **Epoxy Resins**: Often used as a protective coating, epoxy resins help to insulate and protect resistors from environmental factors.

C. Additional Components

1. **Lead Wires**: These are necessary for connecting resistors to circuits.

2. **Protective Coatings**: Coatings are applied to resistors to enhance durability and resistance to environmental factors.

IV. The Production Process

The production of resistors involves several key steps, each critical to ensuring the quality and performance of the final product.

A. Design and Engineering

The process begins with design and engineering, where specifications and requirements are established. Engineers create prototypes and conduct testing to ensure that the resistors meet the desired performance criteria.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing and conducting quality control on raw materials to ensure they meet industry standards. Pre-processing of materials, such as grinding carbon or cutting metal wire, is also performed to prepare for manufacturing.

C. Manufacturing Steps

1. **Mixing and Forming**:

- For carbon composition and film resistors, the conductive materials are mixed with binding agents and formed into the desired shape.

- Wirewound resistors are created by winding metal wire around a ceramic core.

2. **Sintering and Curing**:

- High-temperature processes are employed to sinter ceramic and metal components, enhancing their structural integrity and electrical properties.

3. **Cutting and Shaping**:

- Precision cutting is performed to achieve the exact dimensions required for film and wirewound resistors.

4. **Assembly**:

- Components are integrated, and lead wires are attached to complete the assembly of the resistors.

D. Quality Control

Quality control is a critical aspect of resistor production. Each batch of resistors undergoes rigorous testing to ensure they meet specified resistance values. Environmental and durability testing is also conducted to assess performance under various conditions. Compliance with industry standards is verified to ensure reliability and safety.

V. Packaging and Distribution

Once the resistors have passed quality control, they are prepared for packaging and distribution.

A. Packaging Techniques

1. **Bulk Packaging vs. Individual Packaging**: Depending on customer requirements, resistors may be packaged in bulk for manufacturers or individually for retail distribution.

2. **Labeling and Documentation**: Proper labeling and documentation are essential for traceability and compliance with industry regulations.

B. Distribution Channels

Resistors are distributed through various channels, including direct sales to manufacturers and wholesale or retail distribution. Efficient logistics are crucial to ensure timely delivery to customers.

VI. Environmental Considerations

As the electronics industry grows, so does the need for sustainable practices in resistor manufacturing.

A. Waste Management

1. **Recycling of Materials**: Many resistor factories implement recycling programs to minimize waste and reduce environmental impact.

2. **Disposal of Hazardous Materials**: Proper disposal methods are employed for hazardous materials to comply with environmental regulations.

B. Energy Consumption

1. **Sustainable Practices in Manufacturing**: Factories are increasingly adopting sustainable practices, such as using renewable energy sources and optimizing production processes to reduce energy consumption.

2. **Innovations in Energy Efficiency**: Technological advancements are leading to more energy-efficient manufacturing processes, further reducing the environmental footprint of resistor production.

VII. Future Trends in Resistor Manufacturing

The resistor manufacturing industry is poised for significant changes driven by technological advancements and market demands.

A. Technological Advancements

1. **Automation and Robotics in Production**: The integration of automation and robotics is streamlining production processes, improving efficiency, and reducing labor costs.

2. **Smart Resistors and IoT Applications**: The rise of the Internet of Things (IoT) is driving demand for smart resistors that can provide real-time data and enhance connectivity in electronic devices.

B. Market Demand and Adaptation

1. **Growing Electronics Market**: As the electronics market continues to expand, resistor manufacturers must adapt to meet the increasing demand for high-quality components.

2. **Customization and Niche Markets**: There is a growing trend towards customization, with manufacturers offering tailored solutions to meet specific customer needs.

VIII. Conclusion

In summary, the production process of mainstream resistor factories is a complex and multifaceted operation that involves careful design, material preparation, manufacturing, quality control, and distribution. The significance of quality and innovation in the industry cannot be overstated, as these factors directly impact the performance and reliability of electronic devices. As the industry evolves, embracing sustainable practices and technological advancements will be crucial for meeting the demands of the future. The resistor manufacturing landscape is set to change, and those who adapt will thrive in this dynamic environment.

The Production Process of Mainstream Resistor Factories

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling the flow of electric current. They are essential for regulating voltage, dividing signals, and protecting sensitive components from excessive current. The resistor manufacturing industry has evolved significantly over the years, driven by advancements in technology and the growing demand for electronic devices. This article aims to explore the production process of mainstream resistor factories, shedding light on the intricate steps involved in creating these vital components.

II. Types of Resistors

Resistors come in various types, each designed for specific applications. Understanding these types is essential for grasping the production process.

A. Fixed Resistors

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and are often used in high-power applications.

2. **Film Resistors**: These include carbon film and metal film resistors, which are created by depositing a thin layer of resistive material onto a substrate. They offer better precision and stability compared to carbon composition resistors.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic core, these resistors are capable of handling high power and are often used in applications requiring high precision.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in volume controls and other applications where variable resistance is needed.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are used in applications like dimmer switches.

C. Specialty Resistors

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure and are commonly used in light-sensing applications.

III. Raw Materials Used in Resistor Production

The production of resistors requires a variety of raw materials, each contributing to the final product's performance and reliability.

A. Conductive Materials

1. **Carbon**: Used primarily in carbon composition and carbon film resistors, carbon provides a stable resistive element.

2. **Metal Oxides**: Commonly used in film resistors, metal oxides offer high stability and reliability.

3. **Metal Wire**: Essential for wirewound resistors, metal wire is typically made from materials like nickel-chromium or copper.

B. Insulating Materials

1. **Ceramic Substrates**: These are used in wirewound and film resistors to provide electrical insulation and mechanical support.

2. **Epoxy Resins**: Often used as a protective coating, epoxy resins help to insulate and protect resistors from environmental factors.

C. Additional Components

1. **Lead Wires**: These are necessary for connecting resistors to circuits.

2. **Protective Coatings**: Coatings are applied to resistors to enhance durability and resistance to environmental factors.

IV. The Production Process

The production of resistors involves several key steps, each critical to ensuring the quality and performance of the final product.

A. Design and Engineering

The process begins with design and engineering, where specifications and requirements are established. Engineers create prototypes and conduct testing to ensure that the resistors meet the desired performance criteria.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing and conducting quality control on raw materials to ensure they meet industry standards. Pre-processing of materials, such as grinding carbon or cutting metal wire, is also performed to prepare for manufacturing.

C. Manufacturing Steps

1. **Mixing and Forming**:

- For carbon composition and film resistors, the conductive materials are mixed with binding agents and formed into the desired shape.

- Wirewound resistors are created by winding metal wire around a ceramic core.

2. **Sintering and Curing**:

- High-temperature processes are employed to sinter ceramic and metal components, enhancing their structural integrity and electrical properties.

3. **Cutting and Shaping**:

- Precision cutting is performed to achieve the exact dimensions required for film and wirewound resistors.

4. **Assembly**:

- Components are integrated, and lead wires are attached to complete the assembly of the resistors.

D. Quality Control

Quality control is a critical aspect of resistor production. Each batch of resistors undergoes rigorous testing to ensure they meet specified resistance values. Environmental and durability testing is also conducted to assess performance under various conditions. Compliance with industry standards is verified to ensure reliability and safety.

V. Packaging and Distribution

Once the resistors have passed quality control, they are prepared for packaging and distribution.

A. Packaging Techniques

1. **Bulk Packaging vs. Individual Packaging**: Depending on customer requirements, resistors may be packaged in bulk for manufacturers or individually for retail distribution.

2. **Labeling and Documentation**: Proper labeling and documentation are essential for traceability and compliance with industry regulations.

B. Distribution Channels

Resistors are distributed through various channels, including direct sales to manufacturers and wholesale or retail distribution. Efficient logistics are crucial to ensure timely delivery to customers.

VI. Environmental Considerations

As the electronics industry grows, so does the need for sustainable practices in resistor manufacturing.

A. Waste Management

1. **Recycling of Materials**: Many resistor factories implement recycling programs to minimize waste and reduce environmental impact.

2. **Disposal of Hazardous Materials**: Proper disposal methods are employed for hazardous materials to comply with environmental regulations.

B. Energy Consumption

1. **Sustainable Practices in Manufacturing**: Factories are increasingly adopting sustainable practices, such as using renewable energy sources and optimizing production processes to reduce energy consumption.

2. **Innovations in Energy Efficiency**: Technological advancements are leading to more energy-efficient manufacturing processes, further reducing the environmental footprint of resistor production.

VII. Future Trends in Resistor Manufacturing

The resistor manufacturing industry is poised for significant changes driven by technological advancements and market demands.

A. Technological Advancements

1. **Automation and Robotics in Production**: The integration of automation and robotics is streamlining production processes, improving efficiency, and reducing labor costs.

2. **Smart Resistors and IoT Applications**: The rise of the Internet of Things (IoT) is driving demand for smart resistors that can provide real-time data and enhance connectivity in electronic devices.

B. Market Demand and Adaptation

1. **Growing Electronics Market**: As the electronics market continues to expand, resistor manufacturers must adapt to meet the increasing demand for high-quality components.

2. **Customization and Niche Markets**: There is a growing trend towards customization, with manufacturers offering tailored solutions to meet specific customer needs.

VIII. Conclusion

In summary, the production process of mainstream resistor factories is a complex and multifaceted operation that involves careful design, material preparation, manufacturing, quality control, and distribution. The significance of quality and innovation in the industry cannot be overstated, as these factors directly impact the performance and reliability of electronic devices. As the industry evolves, embracing sustainable practices and technological advancements will be crucial for meeting the demands of the future. The resistor manufacturing landscape is set to change, and those who adapt will thrive in this dynamic environment.