What are the Product Standards for Automotive Resistors?

I. Introduction

Automotive resistors are essential components in modern vehicles, playing a critical role in various electrical and electronic systems. These components help manage current flow, regulate voltage, and ensure the proper functioning of numerous automotive applications, from engine control units to infotainment systems. Given their importance, adhering to product standards is crucial for ensuring the safety, reliability, and performance of automotive resistors. This blog post will explore the types of automotive resistors, key standards and regulations, testing and certification processes, material and design considerations, challenges in meeting standards, and future trends in automotive resistor standards.

II. Types of Automotive Resistors

Automotive resistors can be categorized into several types, each serving specific functions within a vehicle's electrical system.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption capability and are often used in applications where high pulse power is required.

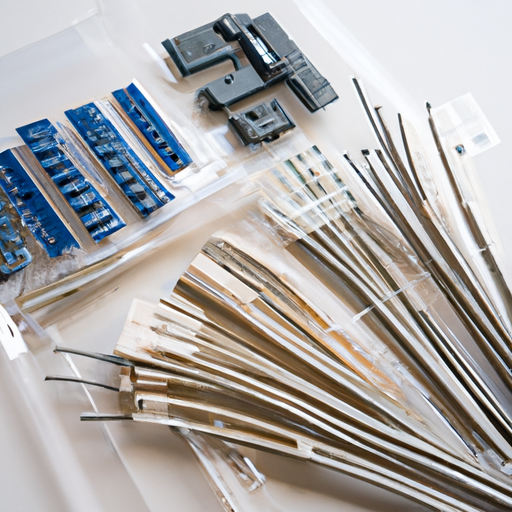

2. **Metal Film Resistors**: These resistors offer better stability and tolerance compared to carbon composition resistors. They are commonly used in precision applications due to their low noise and high reliability.

3. **Wire-Wound Resistors**: Constructed by winding a metal wire around a ceramic or insulating core, wire-wound resistors can handle high power levels and are often used in applications requiring high precision and stability.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in applications such as volume controls in audio systems and as position sensors.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications requiring high power handling.

C. Specialty Resistors

1. **High-Power Resistors**: Designed to handle significant amounts of power, these resistors are used in applications such as electric braking systems and regenerative braking in electric vehicles.

2. **Precision Resistors**: These resistors are designed for applications requiring high accuracy and stability, such as in automotive sensors and control systems.

III. Key Standards and Regulations

Adhering to established standards and regulations is vital for ensuring the quality and safety of automotive resistors. Various international, national, and regional standards govern the manufacturing and testing of these components.

A. International Standards

1. **ISO (International Organization for Standardization)**:

- **ISO 9001**: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their products.

- **ISO 26262**: This standard addresses functional safety in automotive systems, providing guidelines for the development of safety-related electrical and electronic systems.

2. **IEC (International Electrotechnical Commission)**:

- **IEC 60068**: This standard outlines environmental testing methods for electronic components, including resistors, to ensure they can withstand various environmental conditions.

B. National Standards

1. **SAE (Society of Automotive Engineers)**:

- **SAE J1113**: This standard addresses electromagnetic compatibility, ensuring that automotive components do not interfere with each other.

- **SAE J1939**: This standard defines communication protocols for vehicle networks, ensuring reliable data exchange between components.

2. **ANSI (American National Standards Institute)**: ANSI develops and publishes standards for various industries, including automotive, ensuring safety and performance.

C. Regional Standards

1. **EU Regulations**: The European Union has established regulations that govern the safety and environmental impact of automotive components, including resistors.

2. **Japanese Industrial Standards (JIS)**: JIS provides guidelines for the manufacturing and testing of automotive components in Japan, ensuring quality and safety.

IV. Testing and Certification Processes

A. Importance of Testing

Testing is crucial for ensuring the reliability and safety of automotive resistors. It helps manufacturers identify potential issues and verify that their products meet established standards.

1. **Reliability and Safety**: Rigorous testing ensures that resistors can withstand the harsh conditions of automotive environments, including temperature fluctuations, vibrations, and humidity.

2. **Performance Under Various Conditions**: Testing evaluates how resistors perform under different electrical and environmental conditions, ensuring they function correctly in real-world applications.

B. Common Testing Methods

1. **Thermal Cycling**: This test involves subjecting resistors to extreme temperature variations to assess their performance and reliability.

2. **Vibration Testing**: Resistors are exposed to vibrations to simulate the conditions they will encounter in a vehicle, ensuring they can withstand mechanical stress.

3. **Humidity Testing**: This test evaluates how resistors perform in high-humidity environments, which can affect their reliability and lifespan.

C. Certification Bodies

Several organizations provide certification for automotive resistors, ensuring they meet established standards:

1. **Underwriters Laboratories (UL)**: UL is a global safety certification organization that tests and certifies products for safety and performance.

2. **TÜV Rheinland**: This organization provides testing and certification services for various industries, including automotive, ensuring compliance with international standards.

3. **Intertek**: Intertek offers testing, inspection, and certification services, helping manufacturers ensure their products meet safety and quality standards.

V. Material and Design Considerations

A. Material Selection

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal, or metal oxide, affects the performance and reliability of resistors.

2. **Insulating Materials**: Insulating materials are crucial for preventing short circuits and ensuring the safe operation of resistors.

B. Design Standards

1. **Size and Form Factor**: The design of automotive resistors must consider space constraints within vehicles, ensuring they fit within the available space while maintaining performance.

2. **Heat Dissipation Requirements**: Resistors generate heat during operation, so effective heat dissipation designs are essential to prevent overheating and ensure reliability.

C. Environmental Considerations

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic products, promoting environmental sustainability.

2. **REACH Compliance**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation ensures that chemicals used in manufacturing are safe for human health and the environment.

VI. Challenges in Meeting Standards

A. Rapid Technological Advancements

The automotive industry is evolving rapidly, with advancements in technology leading to new applications and requirements for resistors. Manufacturers must continuously adapt to these changes to meet emerging standards.

B. Increasing Demand for Electric Vehicles (EVs)

The rise of electric vehicles presents new challenges for automotive resistors, as they must be designed to handle higher power levels and operate efficiently in electric drivetrains.

C. Global Supply Chain Issues

Global supply chain disruptions can impact the availability of materials and components, making it challenging for manufacturers to meet standards and deliver products on time.

VII. Future Trends in Automotive Resistor Standards

A. Evolution of Standards with Technology

As technology continues to advance, automotive resistor standards will evolve to address new challenges and requirements, ensuring safety and performance in increasingly complex systems.

B. Focus on Sustainability and Environmental Impact

There is a growing emphasis on sustainability in the automotive industry, leading to the development of standards that promote environmentally friendly materials and manufacturing processes.

C. Integration of Smart Technologies

The integration of smart technologies in vehicles will require new standards for automotive resistors, ensuring they can support advanced features such as connectivity and automation.

VIII. Conclusion

In conclusion, product standards for automotive resistors are essential for ensuring the safety, reliability, and performance of these critical components. By adhering to established standards and regulations, manufacturers can produce high-quality resistors that meet the demands of modern vehicles. As the automotive industry continues to evolve, it is crucial for manufacturers and stakeholders to prioritize compliance with standards, ensuring that automotive resistors can support the future of transportation.

IX. References

1. ISO 9001: Quality Management Systems

2. ISO 26262: Functional Safety in Automotive Systems

3. IEC 60068: Environmental Testing

4. SAE J1113: Electromagnetic Compatibility

5. SAE J1939: Communication Protocols

6. RoHS Directive

7. REACH Regulation

This blog post provides a comprehensive overview of the product standards for automotive resistors, highlighting their importance in ensuring safety and performance in the automotive industry.

What are the Product Standards for Automotive Resistors?

I. Introduction

Automotive resistors are essential components in modern vehicles, playing a critical role in various electrical and electronic systems. These components help manage current flow, regulate voltage, and ensure the proper functioning of numerous automotive applications, from engine control units to infotainment systems. Given their importance, adhering to product standards is crucial for ensuring the safety, reliability, and performance of automotive resistors. This blog post will explore the types of automotive resistors, key standards and regulations, testing and certification processes, material and design considerations, challenges in meeting standards, and future trends in automotive resistor standards.

II. Types of Automotive Resistors

Automotive resistors can be categorized into several types, each serving specific functions within a vehicle's electrical system.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption capability and are often used in applications where high pulse power is required.

2. **Metal Film Resistors**: These resistors offer better stability and tolerance compared to carbon composition resistors. They are commonly used in precision applications due to their low noise and high reliability.

3. **Wire-Wound Resistors**: Constructed by winding a metal wire around a ceramic or insulating core, wire-wound resistors can handle high power levels and are often used in applications requiring high precision and stability.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in applications such as volume controls in audio systems and as position sensors.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications requiring high power handling.

C. Specialty Resistors

1. **High-Power Resistors**: Designed to handle significant amounts of power, these resistors are used in applications such as electric braking systems and regenerative braking in electric vehicles.

2. **Precision Resistors**: These resistors are designed for applications requiring high accuracy and stability, such as in automotive sensors and control systems.

III. Key Standards and Regulations

Adhering to established standards and regulations is vital for ensuring the quality and safety of automotive resistors. Various international, national, and regional standards govern the manufacturing and testing of these components.

A. International Standards

1. **ISO (International Organization for Standardization)**:

- **ISO 9001**: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their products.

- **ISO 26262**: This standard addresses functional safety in automotive systems, providing guidelines for the development of safety-related electrical and electronic systems.

2. **IEC (International Electrotechnical Commission)**:

- **IEC 60068**: This standard outlines environmental testing methods for electronic components, including resistors, to ensure they can withstand various environmental conditions.

B. National Standards

1. **SAE (Society of Automotive Engineers)**:

- **SAE J1113**: This standard addresses electromagnetic compatibility, ensuring that automotive components do not interfere with each other.

- **SAE J1939**: This standard defines communication protocols for vehicle networks, ensuring reliable data exchange between components.

2. **ANSI (American National Standards Institute)**: ANSI develops and publishes standards for various industries, including automotive, ensuring safety and performance.

C. Regional Standards

1. **EU Regulations**: The European Union has established regulations that govern the safety and environmental impact of automotive components, including resistors.

2. **Japanese Industrial Standards (JIS)**: JIS provides guidelines for the manufacturing and testing of automotive components in Japan, ensuring quality and safety.

IV. Testing and Certification Processes

A. Importance of Testing

Testing is crucial for ensuring the reliability and safety of automotive resistors. It helps manufacturers identify potential issues and verify that their products meet established standards.

1. **Reliability and Safety**: Rigorous testing ensures that resistors can withstand the harsh conditions of automotive environments, including temperature fluctuations, vibrations, and humidity.

2. **Performance Under Various Conditions**: Testing evaluates how resistors perform under different electrical and environmental conditions, ensuring they function correctly in real-world applications.

B. Common Testing Methods

1. **Thermal Cycling**: This test involves subjecting resistors to extreme temperature variations to assess their performance and reliability.

2. **Vibration Testing**: Resistors are exposed to vibrations to simulate the conditions they will encounter in a vehicle, ensuring they can withstand mechanical stress.

3. **Humidity Testing**: This test evaluates how resistors perform in high-humidity environments, which can affect their reliability and lifespan.

C. Certification Bodies

Several organizations provide certification for automotive resistors, ensuring they meet established standards:

1. **Underwriters Laboratories (UL)**: UL is a global safety certification organization that tests and certifies products for safety and performance.

2. **TÜV Rheinland**: This organization provides testing and certification services for various industries, including automotive, ensuring compliance with international standards.

3. **Intertek**: Intertek offers testing, inspection, and certification services, helping manufacturers ensure their products meet safety and quality standards.

V. Material and Design Considerations

A. Material Selection

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal, or metal oxide, affects the performance and reliability of resistors.

2. **Insulating Materials**: Insulating materials are crucial for preventing short circuits and ensuring the safe operation of resistors.

B. Design Standards

1. **Size and Form Factor**: The design of automotive resistors must consider space constraints within vehicles, ensuring they fit within the available space while maintaining performance.

2. **Heat Dissipation Requirements**: Resistors generate heat during operation, so effective heat dissipation designs are essential to prevent overheating and ensure reliability.

C. Environmental Considerations

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic products, promoting environmental sustainability.

2. **REACH Compliance**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation ensures that chemicals used in manufacturing are safe for human health and the environment.

VI. Challenges in Meeting Standards

A. Rapid Technological Advancements

The automotive industry is evolving rapidly, with advancements in technology leading to new applications and requirements for resistors. Manufacturers must continuously adapt to these changes to meet emerging standards.

B. Increasing Demand for Electric Vehicles (EVs)

The rise of electric vehicles presents new challenges for automotive resistors, as they must be designed to handle higher power levels and operate efficiently in electric drivetrains.

C. Global Supply Chain Issues

Global supply chain disruptions can impact the availability of materials and components, making it challenging for manufacturers to meet standards and deliver products on time.

VII. Future Trends in Automotive Resistor Standards

A. Evolution of Standards with Technology

As technology continues to advance, automotive resistor standards will evolve to address new challenges and requirements, ensuring safety and performance in increasingly complex systems.

B. Focus on Sustainability and Environmental Impact

There is a growing emphasis on sustainability in the automotive industry, leading to the development of standards that promote environmentally friendly materials and manufacturing processes.

C. Integration of Smart Technologies

The integration of smart technologies in vehicles will require new standards for automotive resistors, ensuring they can support advanced features such as connectivity and automation.

VIII. Conclusion

In conclusion, product standards for automotive resistors are essential for ensuring the safety, reliability, and performance of these critical components. By adhering to established standards and regulations, manufacturers can produce high-quality resistors that meet the demands of modern vehicles. As the automotive industry continues to evolve, it is crucial for manufacturers and stakeholders to prioritize compliance with standards, ensuring that automotive resistors can support the future of transportation.

IX. References

1. ISO 9001: Quality Management Systems

2. ISO 26262: Functional Safety in Automotive Systems

3. IEC 60068: Environmental Testing

4. SAE J1113: Electromagnetic Compatibility

5. SAE J1939: Communication Protocols

6. RoHS Directive

7. REACH Regulation

This blog post provides a comprehensive overview of the product standards for automotive resistors, highlighting their importance in ensuring safety and performance in the automotive industry.