What are the Product Features of High Voltage Resistors?

I. Introduction

High voltage resistors are essential components in various electrical and electronic applications, designed to handle high voltage levels safely and effectively. These resistors play a critical role in ensuring the stability and reliability of circuits that operate under high voltage conditions. In this article, we will explore the key product features of high voltage resistors, their applications, and considerations for selecting the right resistor for specific needs.

II. Understanding High Voltage Resistors

A. What Constitutes High Voltage?

In electrical terms, high voltage typically refers to voltages above 1,000 volts (1 kV) for alternating current (AC) and 1,500 volts (1.5 kV) for direct current (DC). High voltage resistors are specifically designed to withstand these elevated levels without breaking down or failing. Applications that require high voltage resistors include power supply systems, testing and measurement equipment, telecommunications, and industrial machinery.

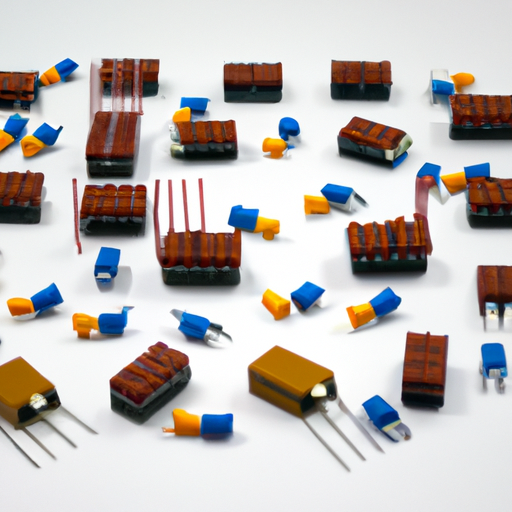

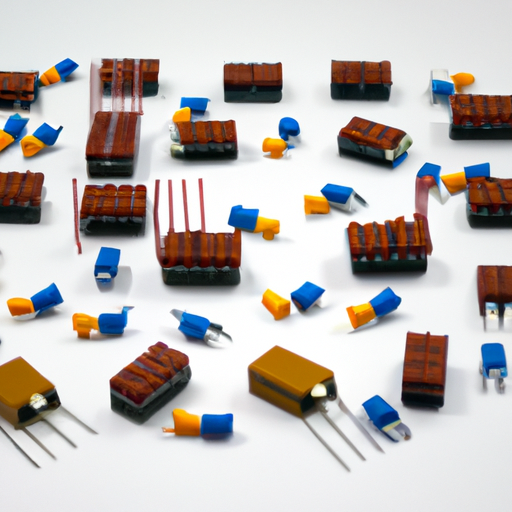

B. Types of High Voltage Resistors

High voltage resistors can be categorized into three main types:

1. **Fixed Resistors**: These resistors have a predetermined resistance value and are commonly used in applications where a stable resistance is required.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance values, making them suitable for applications that require fine-tuning.

3. **Specialty Resistors**: This category includes resistors designed for specific applications, such as high precision, high power, or high-frequency applications.

III. Key Product Features of High Voltage Resistors

A. Voltage Rating

The voltage rating of a high voltage resistor indicates the maximum voltage the resistor can handle without risk of breakdown. This feature is crucial for ensuring the safety and reliability of electrical systems. When selecting a resistor, it is essential to choose one with a voltage rating that exceeds the maximum voltage expected in the application.

B. Power Rating

Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is typically measured in watts (W). The power rating is vital for performance and safety, as exceeding this rating can lead to resistor failure or damage to the circuit. High voltage resistors often have higher power ratings to accommodate the demands of high voltage applications.

C. Resistance Value

High voltage resistors come in a wide range of resistance values, typically measured in ohms (Ω). The resistance value is critical for determining how much current will flow through the circuit. Additionally, tolerance levels indicate how much the actual resistance can vary from the specified value, which is significant for precision applications.

D. Temperature Coefficient

The temperature coefficient measures how much a resistor's resistance changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C). A low temperature coefficient is desirable in high voltage resistors, as it ensures stable performance across varying environmental conditions. This feature is particularly important in applications where temperature fluctuations are common.

E. Construction Materials

The materials used in the construction of high voltage resistors significantly influence their performance and durability. Common materials include:

Carbon: Often used for fixed resistors, carbon resistors are cost-effective but may have higher temperature coefficients.

Metal Film: Known for their precision and stability, metal film resistors are suitable for applications requiring high accuracy.

Wirewound: These resistors are made by winding a metal wire around a core and are capable of handling high power levels, making them ideal for high voltage applications.

F. Insulation Resistance

Insulation resistance is a measure of how well a resistor can prevent electrical leakage. High insulation resistance is crucial for high voltage resistors to ensure safety and prevent short circuits. This feature is typically measured in megohms (MΩ) and is subject to industry standards.

G. Size and Form Factor

The physical dimensions and form factor of high voltage resistors are important for integration into electronic circuits. Resistors come in various sizes, and their mounting options can include through-hole or surface mount configurations. The choice of size and form factor can affect the overall design and layout of the circuit.

H. Environmental Ratings

High voltage resistors are often subjected to harsh environmental conditions. Environmental ratings, such as Ingress Protection (IP) ratings, indicate the resistor's ability to withstand dust and moisture. Additionally, the operating temperature range specifies the conditions under which the resistor can function reliably.

I. Reliability and Lifespan

The reliability and expected lifespan of high voltage resistors are influenced by several factors, including operating conditions, thermal management, and material quality. High-quality resistors are designed to provide long-term stability and performance, reducing the need for frequent replacements.

IV. Applications of High Voltage Resistors

High voltage resistors find applications in various fields, including:

A. Power Supply Systems

In power supply systems, high voltage resistors are used to regulate voltage levels, protect circuits from overcurrent, and ensure stable operation.

B. Testing and Measurement Equipment

High voltage resistors are essential in testing and measurement equipment, where they help simulate load conditions and ensure accurate readings.

C. Telecommunications

In telecommunications, high voltage resistors are used in signal processing and transmission systems to maintain signal integrity and prevent interference.

D. Industrial Equipment

High voltage resistors are commonly found in industrial equipment, where they are used for motor control, power distribution, and safety applications.

E. Medical Devices

In medical devices, high voltage resistors play a critical role in ensuring the safety and reliability of equipment used in diagnostics and treatment.

V. Selecting the Right High Voltage Resistor

A. Factors to Consider

When selecting a high voltage resistor, several factors should be considered:

1. **Application Requirements**: Understand the specific needs of the application, including voltage, power, and resistance requirements.

2. **Environmental Conditions**: Consider the operating environment, including temperature, humidity, and potential exposure to contaminants.

3. **Budget Constraints**: Evaluate the cost of the resistor in relation to its performance and reliability.

B. Common Mistakes to Avoid

1. **Underestimating Voltage and Power Ratings**: Choosing a resistor with insufficient voltage or power ratings can lead to failure and safety hazards.

2. **Ignoring Temperature Coefficients**: Failing to consider the temperature coefficient can result in inaccurate performance in varying conditions.

VI. Conclusion

In summary, high voltage resistors are critical components in many electrical and electronic applications. Understanding their key features, such as voltage rating, power rating, resistance value, and construction materials, is essential for selecting the right resistor for specific needs. As technology advances, high voltage resistors will continue to evolve, offering improved performance and reliability for a wide range of applications.

VII. References

- Suggested reading and resources on high voltage resistors and their applications.

- Industry standards and guidelines for selecting and using high voltage resistors.

By understanding the product features of high voltage resistors, engineers and designers can make informed decisions that enhance the safety and performance of their electrical systems.

What are the Product Features of High Voltage Resistors?

I. Introduction

High voltage resistors are essential components in various electrical and electronic applications, designed to handle high voltage levels safely and effectively. These resistors play a critical role in ensuring the stability and reliability of circuits that operate under high voltage conditions. In this article, we will explore the key product features of high voltage resistors, their applications, and considerations for selecting the right resistor for specific needs.

II. Understanding High Voltage Resistors

A. What Constitutes High Voltage?

In electrical terms, high voltage typically refers to voltages above 1,000 volts (1 kV) for alternating current (AC) and 1,500 volts (1.5 kV) for direct current (DC). High voltage resistors are specifically designed to withstand these elevated levels without breaking down or failing. Applications that require high voltage resistors include power supply systems, testing and measurement equipment, telecommunications, and industrial machinery.

B. Types of High Voltage Resistors

High voltage resistors can be categorized into three main types:

1. **Fixed Resistors**: These resistors have a predetermined resistance value and are commonly used in applications where a stable resistance is required.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance values, making them suitable for applications that require fine-tuning.

3. **Specialty Resistors**: This category includes resistors designed for specific applications, such as high precision, high power, or high-frequency applications.

III. Key Product Features of High Voltage Resistors

A. Voltage Rating

The voltage rating of a high voltage resistor indicates the maximum voltage the resistor can handle without risk of breakdown. This feature is crucial for ensuring the safety and reliability of electrical systems. When selecting a resistor, it is essential to choose one with a voltage rating that exceeds the maximum voltage expected in the application.

B. Power Rating

Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is typically measured in watts (W). The power rating is vital for performance and safety, as exceeding this rating can lead to resistor failure or damage to the circuit. High voltage resistors often have higher power ratings to accommodate the demands of high voltage applications.

C. Resistance Value

High voltage resistors come in a wide range of resistance values, typically measured in ohms (Ω). The resistance value is critical for determining how much current will flow through the circuit. Additionally, tolerance levels indicate how much the actual resistance can vary from the specified value, which is significant for precision applications.

D. Temperature Coefficient

The temperature coefficient measures how much a resistor's resistance changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C). A low temperature coefficient is desirable in high voltage resistors, as it ensures stable performance across varying environmental conditions. This feature is particularly important in applications where temperature fluctuations are common.

E. Construction Materials

The materials used in the construction of high voltage resistors significantly influence their performance and durability. Common materials include:

Carbon: Often used for fixed resistors, carbon resistors are cost-effective but may have higher temperature coefficients.

Metal Film: Known for their precision and stability, metal film resistors are suitable for applications requiring high accuracy.

Wirewound: These resistors are made by winding a metal wire around a core and are capable of handling high power levels, making them ideal for high voltage applications.

F. Insulation Resistance

Insulation resistance is a measure of how well a resistor can prevent electrical leakage. High insulation resistance is crucial for high voltage resistors to ensure safety and prevent short circuits. This feature is typically measured in megohms (MΩ) and is subject to industry standards.

G. Size and Form Factor

The physical dimensions and form factor of high voltage resistors are important for integration into electronic circuits. Resistors come in various sizes, and their mounting options can include through-hole or surface mount configurations. The choice of size and form factor can affect the overall design and layout of the circuit.

H. Environmental Ratings

High voltage resistors are often subjected to harsh environmental conditions. Environmental ratings, such as Ingress Protection (IP) ratings, indicate the resistor's ability to withstand dust and moisture. Additionally, the operating temperature range specifies the conditions under which the resistor can function reliably.

I. Reliability and Lifespan

The reliability and expected lifespan of high voltage resistors are influenced by several factors, including operating conditions, thermal management, and material quality. High-quality resistors are designed to provide long-term stability and performance, reducing the need for frequent replacements.

IV. Applications of High Voltage Resistors

High voltage resistors find applications in various fields, including:

A. Power Supply Systems

In power supply systems, high voltage resistors are used to regulate voltage levels, protect circuits from overcurrent, and ensure stable operation.

B. Testing and Measurement Equipment

High voltage resistors are essential in testing and measurement equipment, where they help simulate load conditions and ensure accurate readings.

C. Telecommunications

In telecommunications, high voltage resistors are used in signal processing and transmission systems to maintain signal integrity and prevent interference.

D. Industrial Equipment

High voltage resistors are commonly found in industrial equipment, where they are used for motor control, power distribution, and safety applications.

E. Medical Devices

In medical devices, high voltage resistors play a critical role in ensuring the safety and reliability of equipment used in diagnostics and treatment.

V. Selecting the Right High Voltage Resistor

A. Factors to Consider

When selecting a high voltage resistor, several factors should be considered:

1. **Application Requirements**: Understand the specific needs of the application, including voltage, power, and resistance requirements.

2. **Environmental Conditions**: Consider the operating environment, including temperature, humidity, and potential exposure to contaminants.

3. **Budget Constraints**: Evaluate the cost of the resistor in relation to its performance and reliability.

B. Common Mistakes to Avoid

1. **Underestimating Voltage and Power Ratings**: Choosing a resistor with insufficient voltage or power ratings can lead to failure and safety hazards.

2. **Ignoring Temperature Coefficients**: Failing to consider the temperature coefficient can result in inaccurate performance in varying conditions.

VI. Conclusion

In summary, high voltage resistors are critical components in many electrical and electronic applications. Understanding their key features, such as voltage rating, power rating, resistance value, and construction materials, is essential for selecting the right resistor for specific needs. As technology advances, high voltage resistors will continue to evolve, offering improved performance and reliability for a wide range of applications.

VII. References

- Suggested reading and resources on high voltage resistors and their applications.

- Industry standards and guidelines for selecting and using high voltage resistors.

By understanding the product features of high voltage resistors, engineers and designers can make informed decisions that enhance the safety and performance of their electrical systems.